Product Type: Egg Tray Machine

Processing Type: Pulp Molding Machine

Place Of Origin: Shandong, China

Approval: CE

Warranty: 12 Monthes

Rotary: 8 Faces

Forming Platen Size: 2350 x 420 mm

Capacity: 6000 pcs/hr (30-egg tray)

Matches with 6-layer dryer, energy-efficient and conserve energy

Full automatic egg box production line equipped with automatic hot

pressing and intelligent conveying stacking technology.

Mainly applied for egg tray, egg carton, fruit tray, cup carrier,

bottle tray, etc.

Our egg tray machine has four parts: Pulping system, forming

system, drying line and packing part

(1)Pulping system:

Pulping system is mainly comprised of hydrapulpter, pulp pump,

multi-function refiner machine, blender, control cabinet,etc.

It can make the pulp by the waste paper. And it is the first step

in making process!

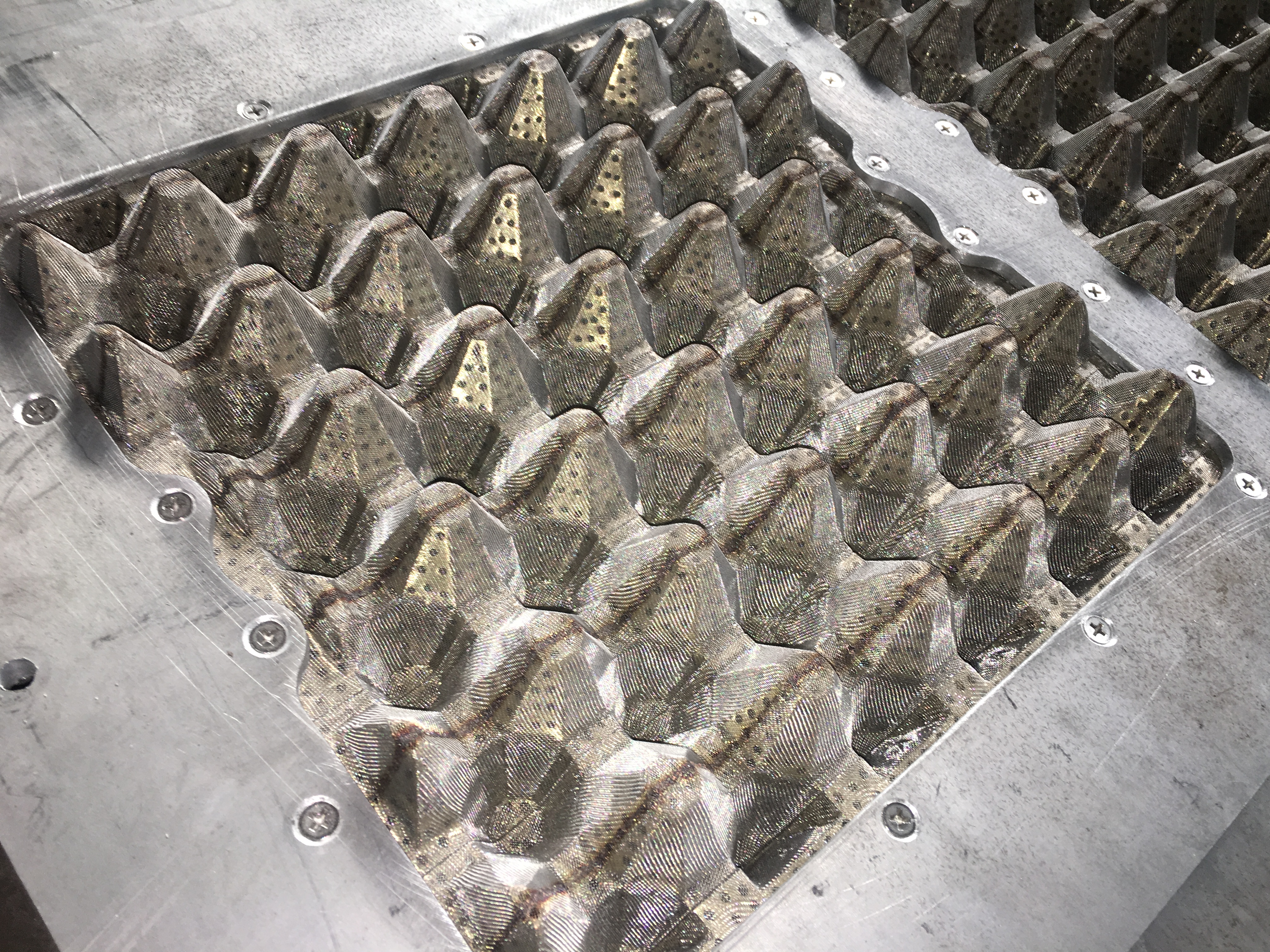

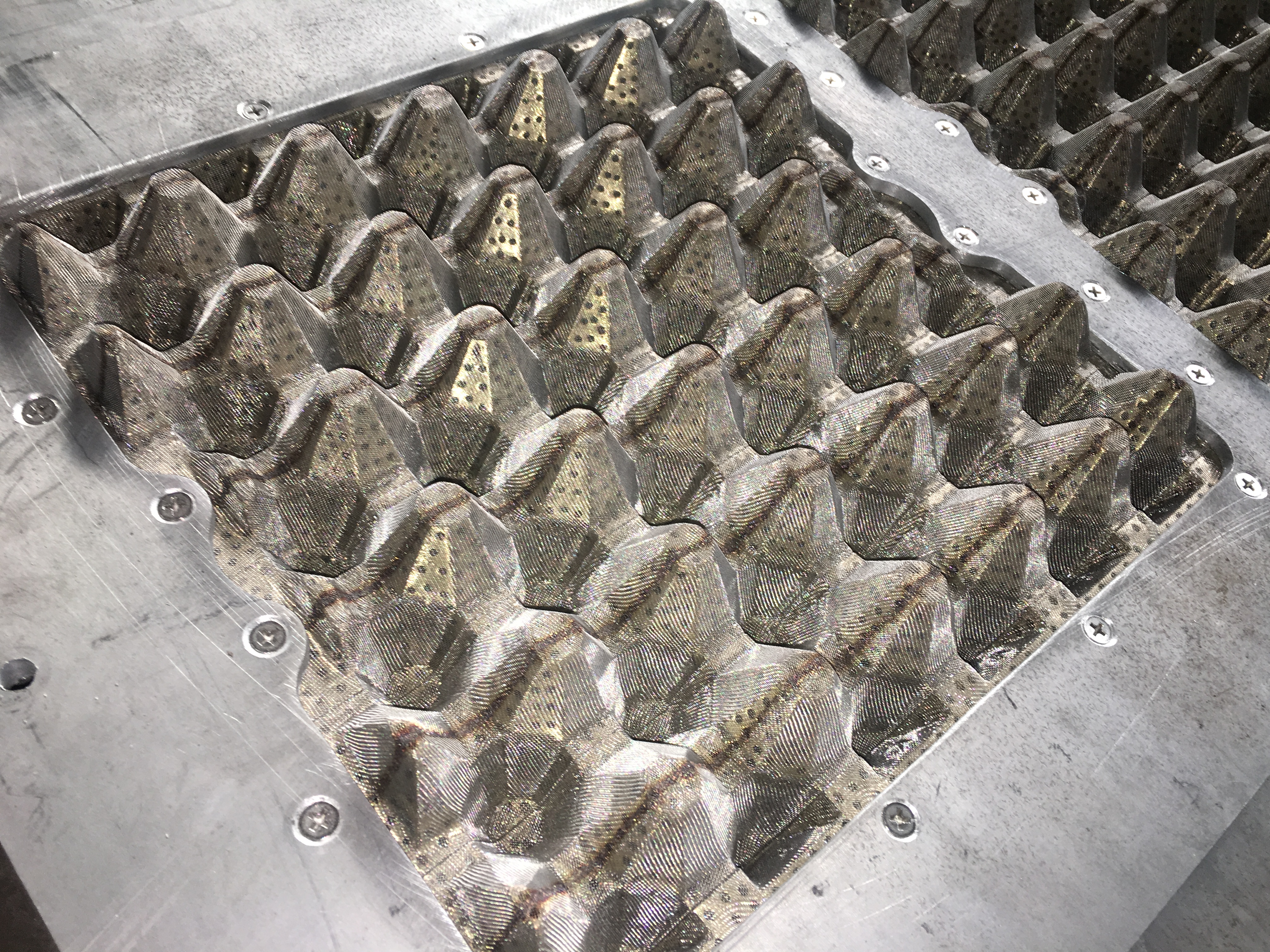

(2)Forming system:

This part mainly is the egg tray forming machine. We could produce

the forming mould and transferring mould based on our customer's

request. The material of the mould could be Aluminum, Resin,

Plastic.

(3)Drying line

This is very important in all of the lines. When the egg tray is

made over by the forming machine, the egg tray will be put on the

drying line, they will across the drying channel, then you can get

the dry tray!

(4)Packing machine

This is the last step when we get the finished tray from the drying

line, we can packing them.

If you want to buy the best egg tray machine or pulp molding

machine, please contact me! I can help you!

Technical data

| Item | Information | Notes |

| Output Range | 6000pcs/h | 30 packed egg tray(60~80g) |

| Workshop recommendation | ≥600m2 | Length≥40m;Width≥15m;Height≥6m; (It could be adjusted according to the user's existing workshop) |

| Type of Material | Waste paper | Newspaper/Carton /Paper box/Books/ Corrugated paper/Kraft paper etc. |

| Material consumption | 360~480kg/h | 30 packed egg tray(60~80g) |

| Water consumption | 800-1050kg/h | 30 packed egg tray(60~80g) |

| Electricity consumption | 140-175kw/h | Full throttle operation |

Fuel consumption (approximately) | LPG 55~70 kg/h | 30 packed egg tray(60~80g) Choose one from these types of fuel |

| Natural gas 85~100 m3/h |

| Diesel 65~80kg/h |

| Operator Required | 5~8 person/shift | 24hours, 3shift |

| Container requirement for Transport | 5 of 40 HQ container + 1 of 20’GP container | Whole production line |

Production flow chart

Mold pictures

ADVANTAGE

1. High efficiency,low energy consume,low noise

2. Easy to operate, low labor force cost,large output

3. Stable final product quality(same weight,dimension,good look)

4. Professional technical support,superior after-sales service

5. Medium investment,high profit

6. optional color

7. excellent after-sales service

Packing & Delivery